In conclusion, the hydropower plant sliding bearing is an extreme application due to its extreme contact pressure during operation (~ 30 MPa), the longevity of operation (~ 40 years), and the necessity to adapt oil-free or water lubrication from a sustainability perspective. Prabakaran Saravanan, Nazanin Emami, in Tribology of Polymer Composites, 2021 6 Conclusion The design of boundary-lubricated bearings is outlined in Section 5.3 and full-film hydrodynamic bearings in Section 5.4.

Mixed-film lubrication is rarely used because it is difficult to quantify the actual value of the coefficient of friction and small changes in, for instance, the viscosity will result in large changes in friction (note the steep gradient in Fig. In general, boundary lubrication is used for slow speed applications where the surface speed is less than approximately 1.5 m/s. By contrast the coefficient of friction for a rolling element bearing is typically of the order of 0.005.

Typical coefficients of friction for a boundary lubricated bearing are between approximately 0.05 and 0.1. Normally, of course, a low coefficient of friction is desirable to ensure that only a small amount of power is necessary to rotate or drive the component concerned. The bearing parameter, μN/ P, groups several of the bearing design variables into one number.

If lubricant under high enough pressure is supplied to the bearing to separate the two surfaces it is called a hydrostatic bearing ( Rowe, 2012). All of these types of lubrication can be encountered in a bearing without external pressuring of the bearing. Here the motion of the surface generates high pressures in the lubricant, which separate the two components and journal can ‘ride’ on a wedge of fluid.

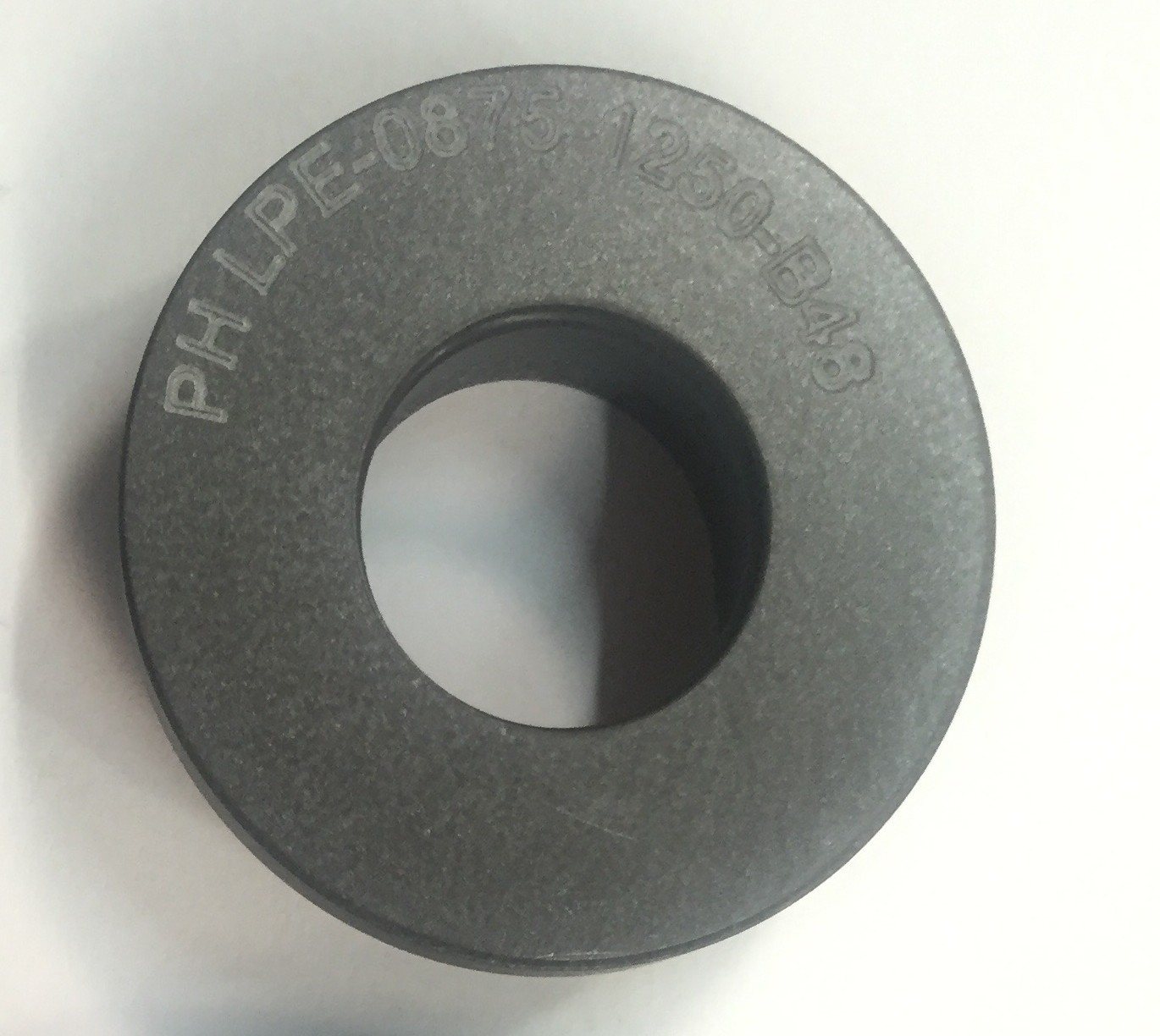

#Bearing isolator full

Full film lubrication occurs at higher relative velocities. There is still contact in places around the circumference between the two components. Mixed film lubrication occurs when the relative motion between the surfaces is sufficient to generate high enough pressures in the lubricant film, which can partially separate the surfaces for periods of time. Although some lubricant may be present, the pressures generated within it will not be significant and the relative motion of the surfaces will bring the corresponding peaks periodically into contact.

#Bearing isolator series

The surfaces, even if ground to a low value of surface roughness, will still consist of a series of peaks and troughs as illustrated schematically in Fig. As a remedy to this, such sliding can be applied in conjunction with some elements that provide restoring force (e.g., LRB or HDRB) or other types of sliding surfaces such as spherical surface can be used ( Kelly, 2001b).īoundary lubrication typically occurs at low relative velocities between the journal and the bearing surfaces and is characterised by actual physical contact. In general, the hysteretic loop of a flat sliding isolator without a restoring force is like a rectangular shape. The friction coefficient in such systems under design earthquakes is in the range of 0.1–0.15 for unlubricated bearings and <0.02 for lubricated bearings ( Tyler, 1977). This is usually a more economical approach than standard elastomeric bearings ( Taylor, 2012). The rubber layer is used to have a uniform bearing stress distribution. PTFE disk, backed by a rubber layer positioned into a slot in a steel plate, which slides against a stainless steel surface.

0 kommentar(er)

0 kommentar(er)